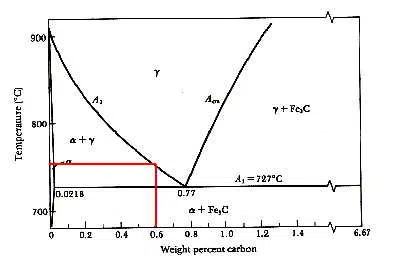

Scientists have known for years that the deep-freezing of metals changes its microstructure. Originally discovered by NASA, this cryogenic treatment relieves stress and produces a more consistent and uniform material.

What’s this do for softball bats? According to research published by Worth Sports Company, cryogenically treated bats result in a 2 to 4% greater hit distance. In addition, the stress relieving properties results in less vibration, improved feel and greater “pop” off the bat.

Research at Alcoa verified that proper cryogenic treatment reduces residual stresses in their aluminum alloys. Alcoa reported that their tests proved that this resulted in an increase of the “trampoline effect” of the bat when striking the ball.

Users report that the ball travels further and that much less vibration is experienced. Bat life is also increased as the cryogenically stress relieved bat is much less susceptible to denting.

It is perfectly legal to play with a cryogenically treated softball bats and Worth Sports Company has adopted the technology in their line of bats. It is a one time, permanent and irreversible treatment.

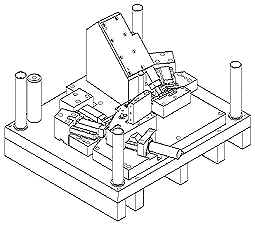

The process involves using a computer controlled chamber to very gradually bring the bats to 300 degrees below zero, holding it there for at least 24 hours, and then gradually returning to room temperature.

Grips and certain plastic caps may be affected (e.g. cracked) by the process. We recommend replacing any parts so affected after treatment, which is not included in our processing charge. While this is a relatively rare phenomenon, it may occur in some cases. Bats received by Friday are ready for pickup or shipment by the following Tuesday.

Cost is $20.00 for 1 bat, or three for $50, plus return freight and insurance (if desired).

If you would like to place an order click on Order Form here or on the left hand side of the page.