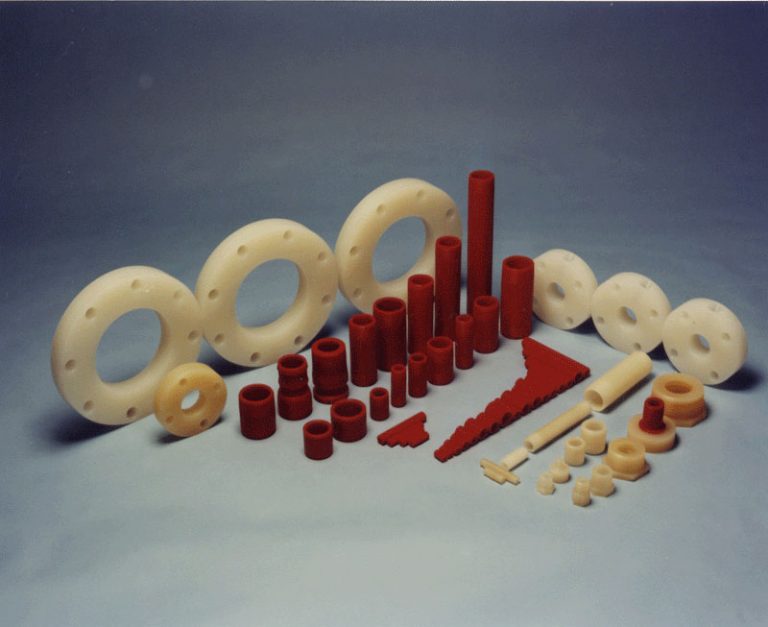

Cryogenic Deflashing Glass-Filled Nylon Introduction Glass-filled nylon is a type of nylon that has been reinforced with short glass fibers. The glass fibers provide reinforcement, making the nylon stronger, harder, and more rigid than regular run of the mill nylon. Glass-filled nylon is often used in applications where strength and durability are important, such as […]