Introduction to Kynar

Kynar is a type of polyvinylidene fluoride, also known as PVDF resin, a high-performance thermoplastic material. PVDF is a fluoropolymer, which means that it is highly resistant to harsh chemicals, ultraviolet radiation, and weathering. This makes it an excellent resin choice for outdoor and industrial applications.

Kynar is known for its exceptional durability and chemical resistance, and is commonly used in applications such as coatings, linings, and piping systems in the chemical processing, semiconductor, and aerospace industries. It is also used in architectural applications, such as coatings for building facades, as it can withstand exposure to UV radiation & weathering, and maintain its color and appearance over time.

Molding Kynar Parts

Kynar can be molded into parts using various molding techniques, including injection molding, compression molding, and extrusion molding.

Injection molding is a process where Kynar resin pellets are heated and melted, and then injected into a mold cavity under high pressure. Once the molten material has cooled and solidified, the mold is opened, and the finished part is removed.

Compression molding involves placing Kynar resin powder or pellets into a heated mold, and then compressing the material under high pressure. The heat and pressure cause the material to melt and flow into the shape of the mold. Once the part has cooled and solidified, the mold is opened, and the finished part is removed.

Extrusion molding is a process where Kynar resin is fed into an extruder, which heats and melts the material, and then forces it through a die to create a continuous shape. The extruded shape can then be cut into desired lengths to create parts.

The specific molding technique used will depend on the desired shape and properties of the final part, as well as the manufacturing capabilities and equipment available.

Applications

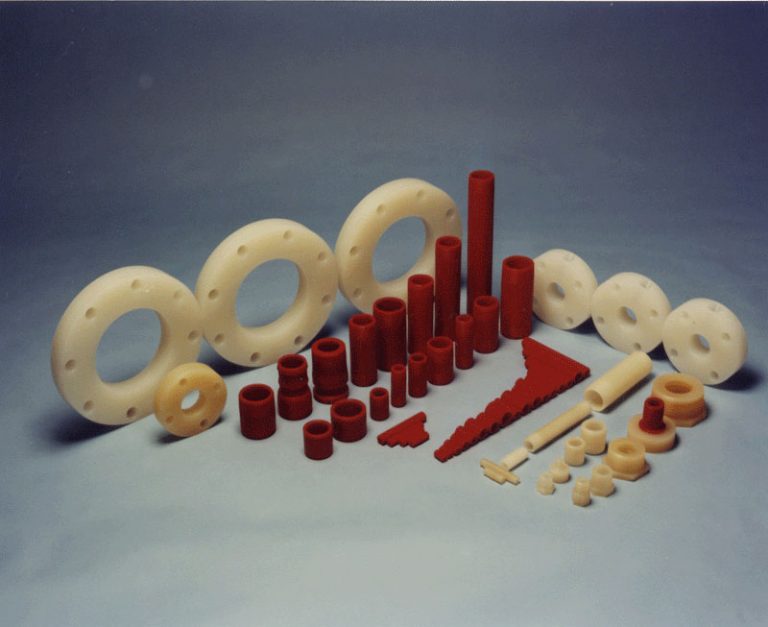

Kynar is used to create molded parts for a wide range of industrial and commercial applications. Some examples of molded Kynar parts and their applications include:

- Pump components: Kynar is often used to mold pump impellers, casings, and other components due to its excellent chemical resistance and high strength.

- Semiconductor components: This material is used to create molded components for semiconductor processing equipment, such as wafer carriers, chambers, and valve seats, due to its high purity, low particle generation, and resistance to chemicals and high temperatures.

- Electrical components: It is used to create molded components for electrical and electronic applications, such as connectors, terminal blocks, and circuit breaker housings, due to its excellent electrical properties and resistance to harsh environments.

- Aerospace components: This plastic material is used to mold components for the aerospace industry, such as fuel and hydraulic system components, due to its resistance to high temperatures, fuels, and chemicals.

- Architectural components: Kynar plastic is used to mold components for architectural applications, such as window frames, wall panels, and roofing systems, due to its UV resistance, weatherability, and color retention properties.

Cryogenic Deflashing Kynar Molded Parts

Kynar parts can be cryogenically deflashed to remove residual mold flashing. Cryogenic deflashing is a process that uses gaseous nitrogen to freeze the molded parts, which causes the residual mold flashing to become brittle and easily break off when the parts are tumbled & blasted with polycarbonate media in a cryogenic deflashing machine.

Cryogenic deflashing is often used for molded parts made from thermoplastics like Kynar, as it is a non-abrasive and non-destructive process that does not damage the surface of the parts. This makes it a preferred method for removing flashing from delicate or complex-shaped parts where traditional deflashing methods like sandblasting or trimming may be difficult or can cause damage to the parts.

Cryogenic deflashing can effectively remove residual mold flashing from Kynar parts, leaving them with a smooth surface finish and consistent dimensions part to part. It is a relatively fast and efficient process that can be used for both small and large quantities of parts.

Want to send us your molded Kynar part samples for a no-cost deflashing evaluation? Contact us at info@nitrofreeze.com or call us at (508) 459-7447×105 to learn more.