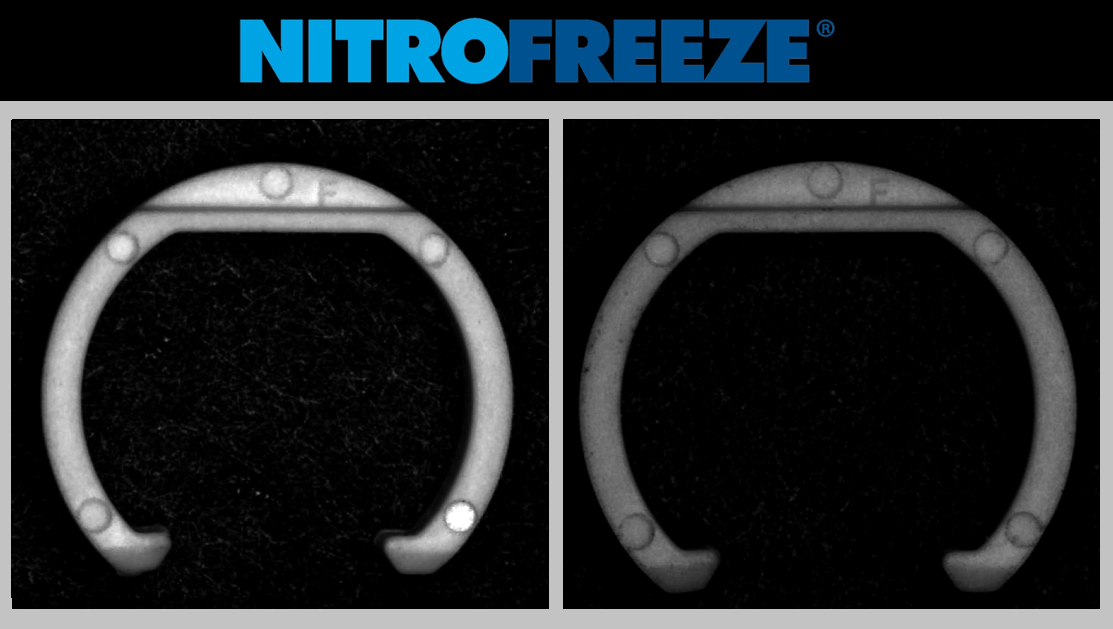

Nitrofreeze® cryogenic deburring removes burrs from glass-filled nylon parts without affecting critical tolerances or surface finish. This computer-controlled, machine-based process is faster than hand deburring and provides more consistent results.…

Read More