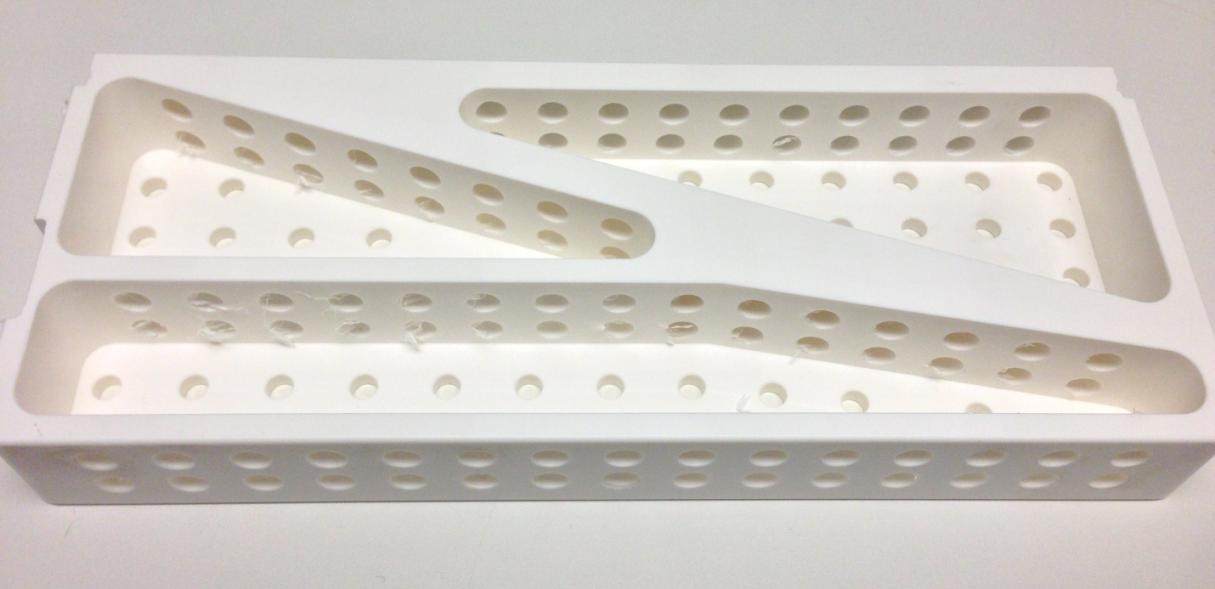

Nitrofreeze® cryogenic deflashing is a quick, consistent, and cost-effective way to remove flash from batches of molded rubber and plastic parts. Flash, a type of manufacturing defect, is excess material that forms on the surfaces of parts produced with injection, compression, or transfer molding. Flash detracts from a part’s appearance, but it can also cause […]