Nitrofreeze® Deflashing and Deburring process adds value while reducing costs to customers by eliminating the need for hand trimming. Highlighted below is an actual customer part that has successfully undergone the…

Read More

Nitrofreeze® Deflashing and Deburring process adds value while reducing costs to customers by eliminating the need for hand trimming. Highlighted below is an actual customer part that has successfully undergone the…

Read More

Nitrofreeze® Deflashing and Deburring process adds value while reducing costs to customers by eliminating the need for hand trimming. Highlighted below is an actual customer part that has successfully undergone the…

Read More

Nitrofreeze® Proof of Concept Case Study- Deflashing Polyurethane Our Cryogenic Deflashing and Deburring process adds value while reducing costs to customers by eliminating the need for hand trimming. Highlighted below is an…

Read More

Nitrofreeze® Proof of Concept Case Study- Deflashing Silicone Our Cryogenic Deflashing and Deburring process adds value while reducing costs to customers by eliminating the need for hand trimming. Highlighted below is…

Read More

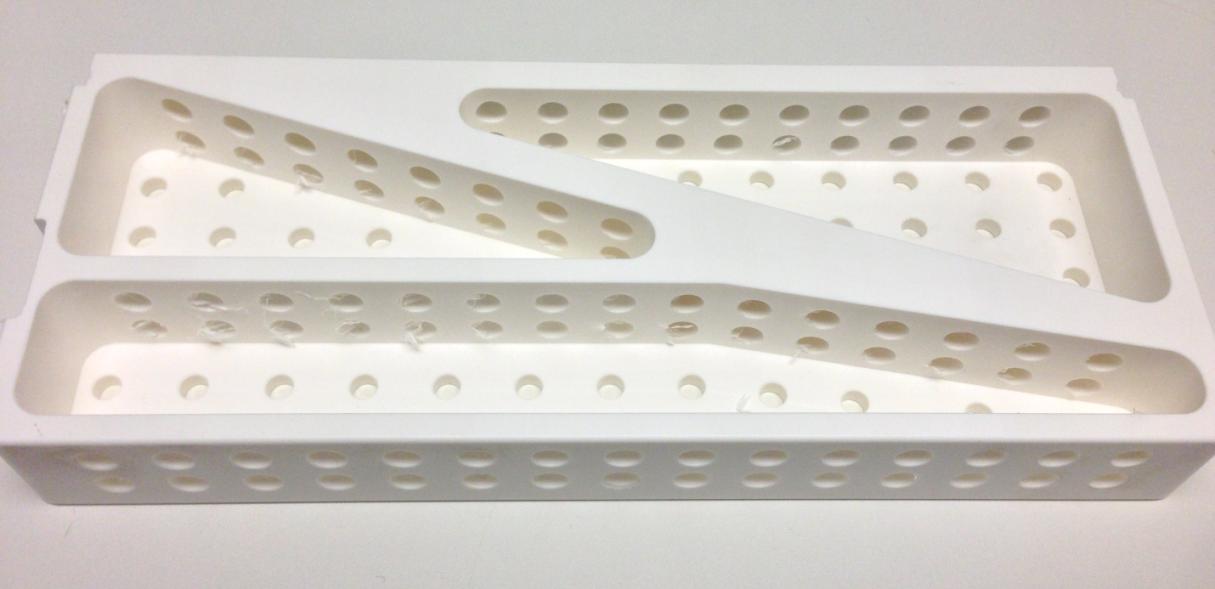

Nitrofreeze Cryogenic Solutions provides services for deburring polypropylene medical parts. Polypropylene is an exceptionally hard plastic with a high tolerance to heat. Due to these…

Read More

Last week Nitrofreeze brought their dry ice blasting equipment, technicians, and accessories to Cranston, Rhode Island during the 4th of July shutdown, to come to the aid of a company…

Read More

The Cryogenic Institute of New England, Inc. provides its proprietary Nitrofreeze Cryogenic Deflashing Service to customers across the United States. Our new facility located in Worcester, Massachusetts has boosted capacity…

Read More

Cryogenic deflashing has existed for several decades to serve the rubber and silicone molding industries. For several decades this process has helped remove residual flash left over by the molding…

Read More

Cross holes can be an issue for many machinists working with plastic materials. As a hole is machined into another hole, burrs will pop up once the tool is removed.…

Read More